High-Precision Compression Molding

Custom Compression Mold Manufacturer

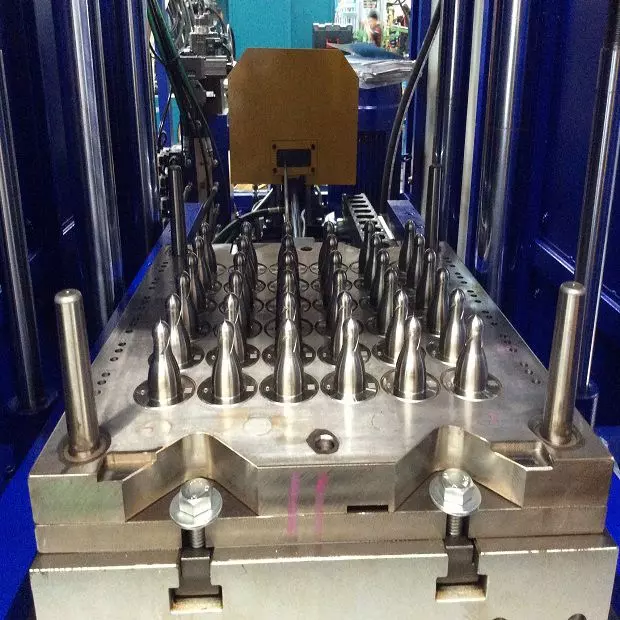

Compression molding process is directly arranging rubber strip above cavity then close mold plate to proceed molding process. Besides the relative production parameters, the mold design focuses on how to have molding pressure spread averagely and how to deal with the going of waste rubber and exhausting air. Furthermore, less flash is always the essential requirement which depends on the design of cutting groove. With good design of cutting groove, not only flash can be easily erased manually, but also can produce good flash-less rubber parts. Cutting groove is also related to the mold life time. The selection of mold steel is an important consideration.

On the other hand, we notice the mold-machining quality in order to have less tool mark (good roughness of surface), accurate dimensions with correct rubber shrinkage rate estimation as well.

To do mold test, we usually require the compound rubber from customer in order to 100% simulate the working conditions at customer's side. The more details we notice with good communication, the higher possibility that we can successfully make a very good quality mold. Besides, doing mold test, we not only provide samples for your evaluation, we will also provide the related production parameters of mass production as your reference which should be able to save your time of study to the best working conditions of operating your molds.

For more information in detail, please make contact with us.

- Download

Tags

How can cutting groove design impact your rubber part quality and production efficiency?

The cutting groove design in compression molds directly influences flash formation, part removal ease, and overall mold lifespan. L&J's precision-engineered cutting grooves minimize flash while facilitating easy manual removal, resulting in near flash-less rubber parts. This reduces post-processing time by up to 40% and extends mold service life significantly. Our expert engineers can customize cutting groove specifications to match your specific rubber compound properties and production requirements.

With 17 years of industry experience, our comprehensive approach includes rigorous mold testing using customer-supplied compound rubber to perfectly simulate actual production conditions. This attention to detail enables us to deliver not only exceptional molds but also valuable production parameters that optimize your manufacturing process. Our precision machining techniques ensure minimal tool marks, accurate dimensions, and correct rubber shrinkage rate calculations. By partnering with L&J International, manufacturers gain a reliable rubber molding solution that combines technical excellence with practical production efficiency.