Metal Case

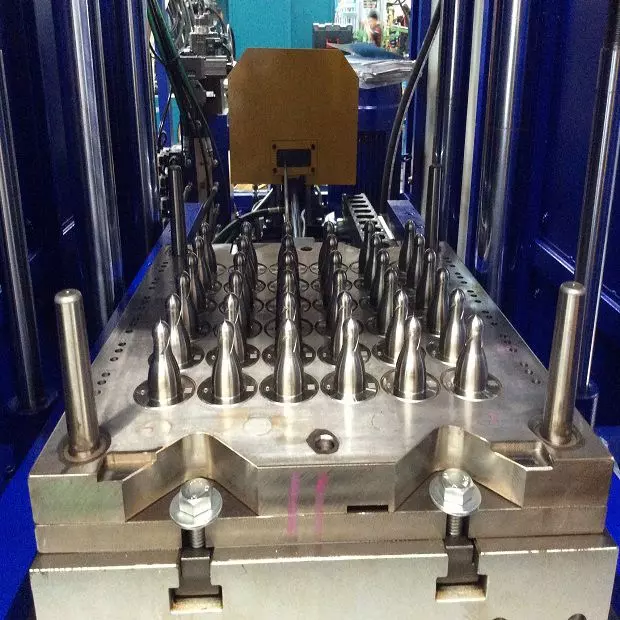

L&J always works with good and professional source in Taiwan. For metal case, the critical key point of quality is the design and accuracy of press mold as well as good production concept in quality control.

The accuracy of metal case is very important to coordinate with compression cavity mold (oil seal). Enquiring L&J, please provide the drawing of metal case design with specification in detail.

How Does Metal Case Precision Impact Your Oil Seal Performance?

The precision of metal cases directly determines oil seal effectiveness and longevity. Even minor deviations can lead to premature seal failure and system leakage. L&J's metal cases are manufactured to exacting standards with tolerances that ensure perfect coordination with compression cavity molds, resulting in optimal sealing performance. Share your specifications with us to discuss how our precision metal cases can enhance your oil seal reliability.

The precision of our metal cases is paramount for proper coordination with oil seal components, directly influencing the sealing system's overall performance and longevity. When inquiring about our metal case solutions, we encourage customers to provide detailed drawings with comprehensive specifications to ensure we deliver products that perfectly match your requirements. With 17 years of industry experience, L&J has established itself as a trusted vertical integration supplier in the rubber industry, offering reliable metal case solutions for various industrial applications.