Spring

Spring is a very important element in oil seal which usually is the critical factor to affect the force of oil seal assembled application. Therefore, high quality spring is able to enhance and improve oil seal performance.

The reason why we are able to provide higher quality spring is mainly from the following 4 factors:

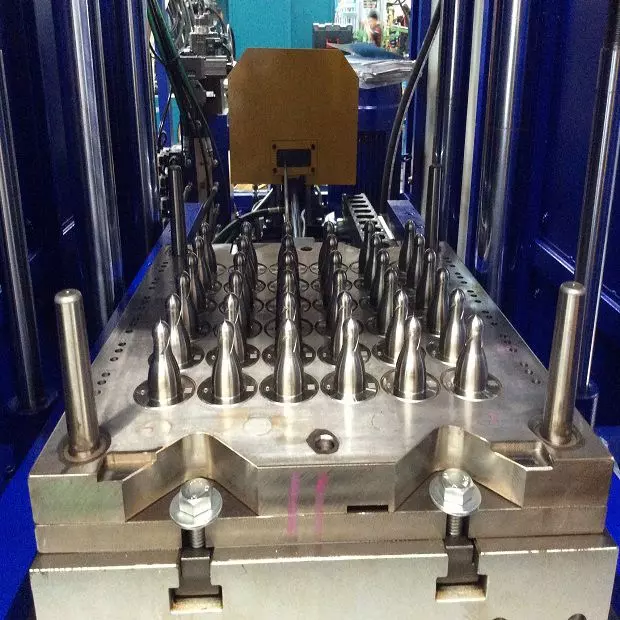

(1) High investment on working facility, like Japan KKS coiling machine, Germany WAFIOS coiling & joining machine, heat treatment furnace, Japan JISC spring loading tester, Italy LTF 2D optical profile projector, SPC software, and so on.

(2) Always use high quality wire steel material from Japan, Germany, and good Taiwanese company.

(3) Well trained people.

(4) With professional and experienced spring working practice for 35 years, we have our own know-how of spring working value to coordinate with diversified oil seal specification and required conditions.

Enquiring L&J, please advise the following information:

(2) Required spring force.?If cannot, we can give suggested force value according to the oil seal specification.

(3) Wire steel material, or suggestion from L&J.

(4) Quantity (important).

(5) Special demand, if you need, like spring test report is essential.

Can Your Current Springs Handle the Pressure Demands of Next-Generation Hydraulic Systems?

Modern hydraulic systems require seals that can withstand higher pressures while maintaining perfect sealing properties. Our advanced manufacturing facilities, including Japan JISC spring loading testers and Germany WAFIOS coiling machines, allow us to produce springs with precisely controlled force characteristics calibrated to your specific application requirements. Send us your hydraulic system specifications, and we'll provide a custom spring solution that optimizes seal performance while preventing fluid leakage under the most demanding operational conditions.

What distinguishes our spring components is our comprehensive vertical integration approach, from material selection to final quality control. We exclusively source high-grade wire steel from Japanese, German, and premium Taiwanese suppliers, ensuring superior metallurgical properties for each application. Our engineering team can provide customized spring solutions based on specific oil seal requirements, with capabilities to manufacture according to precise inner diameter, wire diameter, coil specifications, and force requirements. Each spring undergoes rigorous testing to verify performance under actual operating conditions, ensuring optimal sealing effectiveness in your final products.