Diaphragm

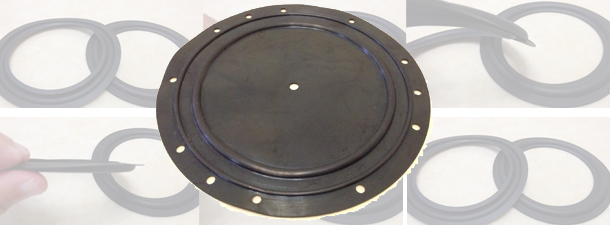

Rubber Diaphragm is widely applied in Brake System, Pump System, Speaker System, and so on. Sometimes, it is bonded with Nylon cloth in order to resist higher pressure. Generally speaking, the choose of rubber material is critical to suit diversified working environmental requirements and this is what we are good at.

Different kinds of diaphragm which we once produced is applied for many ways. Especially we are specialist at diaphragm used for speaker which is higher technology. It requires professional know-how in compound, molding process and speaker working theory to get the strict high quality diaphragm in order to produce a good sound of music.

If you need rubber diaphragm used for speaker, L&J's system is able to work for that well. Please make contact with us.

Different kinds of diaphragm with averagely thin thickness.

How can speaker diaphragm material selection impact sound quality and performance?

The rubber compound formulation in speaker diaphragms directly influences frequency response, damping characteristics, and overall sound reproduction quality. L&J's specialized rubber compounds are engineered specifically for audio applications, delivering the precise balance of flexibility and rigidity needed for accurate sound reproduction across the frequency spectrum. Our technical expertise in both rubber technology and acoustic principles allows us to develop custom diaphragm solutions that achieve superior sound quality for your specific speaker design requirements.

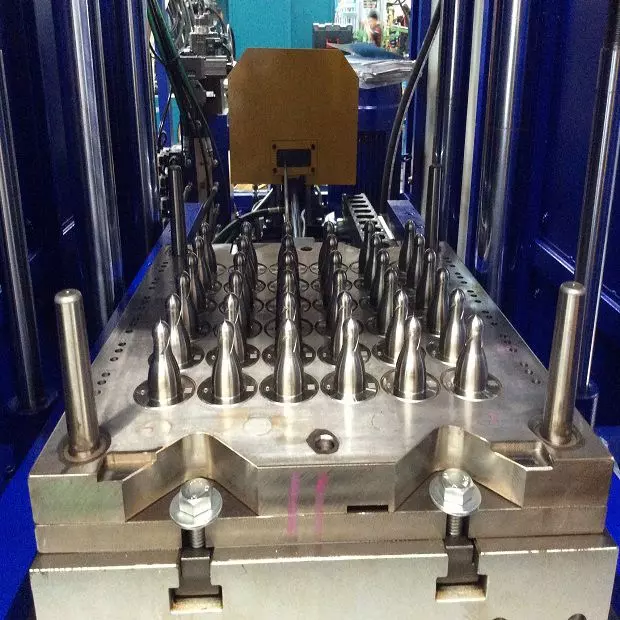

As recognized specialists in speaker diaphragm technology, our manufacturing process combines advanced rubber compounding knowledge with precise molding techniques and acoustic engineering principles. This integration of expertise enables us to produce diaphragms with the exact specifications required for superior sound reproduction. Whether you need components for automotive brake systems, industrial pumps, or high-fidelity speakers, our vertical integration capabilities allow us to control quality throughout the production process, delivering consistent, reliable diaphragms that meet the most demanding specifications.