Introduction - 4 axle CNC Helix Machining Equipment

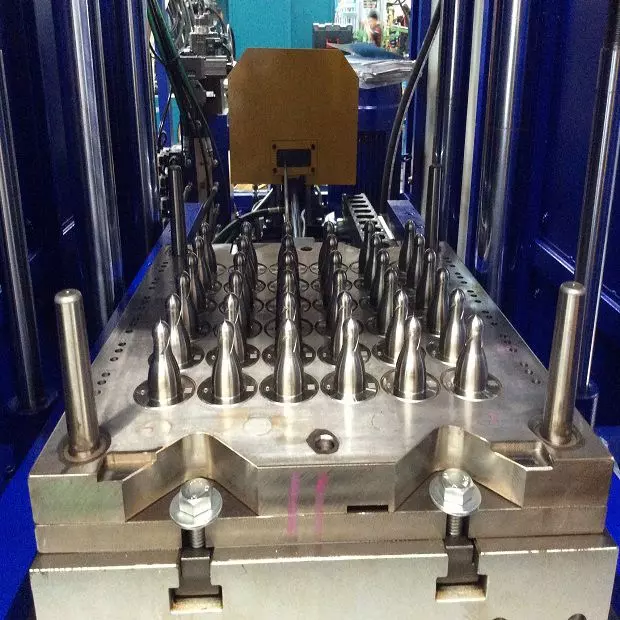

L&J oil seal mold maker has finished the investment of purchasing 4 axle CNC Helix machining equipment in their plant. So, from now on, they will make oil seal Helix by CNC to do the machining which would be very accurate. EDM (Electric Discharge Machining) method is given up. In Taiwan, almost 99% of mold makers still adopt EDM method to make oil seal Helix which is not an accurate way. L&J is the leader of oil seal mold supplier in Taiwan.

Introduction - 4 axle CNC Helix Machining Equipment | Vertical Integration Rubber Solutions for Industrial Applications

L&J International is a vertically integrated supplier providing comprehensive solutions for the rubber industry. Our expertise spans the entire manufacturing process, from compound rubber and rubber machinery to precision-engineered rubber molds and rubber components. By managing every stage of production under one system, we ensure consistent quality, efficiency, and customization to meet unique client requirements.

With over 15 years of manufacturing experience in Taiwan, L&J produces reliable rubber products for industrial applications, including oil seals, O-rings, and other specialized rubber parts. Our advanced facilities and rigorous quality standards enable us to serve diverse industries worldwide, delivering durable and high-performance solutions tailored to your business needs.

L&J has been providing high-quality rubber components, precision molds, and advanced machinery, backed by years of industry expertise. Our commitment to excellence ensures that every customer’s specific requirements are efficiently met with reliable and durable solutions.