Custom International Standard size O Ring and X Ring

L&J specializes in manufacturing high-quality rubber O-Rings and X-Rings, fully compliant with international standard sizes to meet diverse industrial sealing needs. We offer a complete range of O-Rings following global standards, including:

1.AS568 Standard Rubber O-Rings & X-Rings – Widely used in North America and global industries

2.JIS G Standard Rubber O-Rings – Designed for Japanese industrial applications

3.JIS P Series Rubber O-Rings – Precision sealing solutions for various machinery

4.JIS S Standard Rubber O-Rings – Engineered for superior sealing performance

With customization options available, we manufacture OEM & ODM O-Rings tailored to your specific needs. Our products are made from high-performance materials such as NBR, FKM (Viton), EPDM, and Silicone, ensuring resistance to extreme temperatures, chemicals, and pressure.

O Ring Drawing

Advantage

● Precision Customization to Meet Industry Needs

✅ Compliant with international standards (AS568, JIS G, JIS P, JIS S), with custom sizes available

✅ Supports OEM & ODM to design tailor-made sealing solutions

✅ Multiple rubber material options (NBR, FKM/Viton, EPDM, Silicone) for high-temperature, oil-resistant, and chemical-resistant applications

● Taiwan Manufacturing – Consistent Quality & Reliability

✅ ISO-certified factory, adhering to international quality management standards

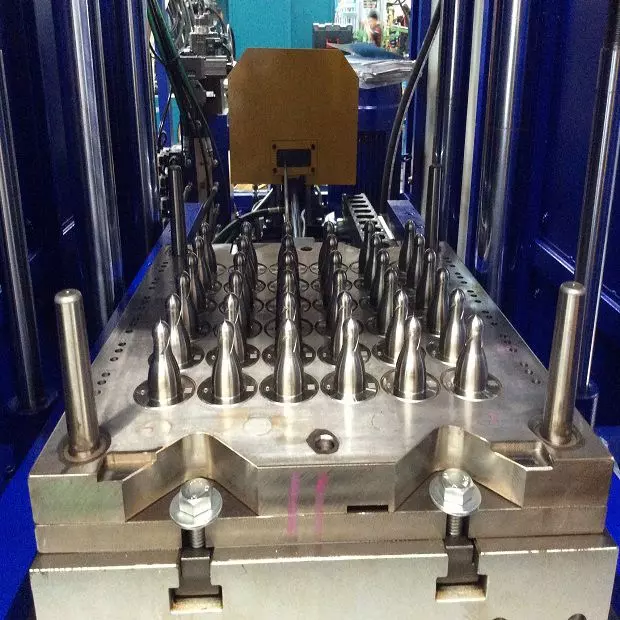

✅ High-precision molding technology ensures accurate O-Ring & X-Ring tolerances for optimal sealing performance

✅ Strict quality control (tensile strength, abrasion resistance, and pressure resistance tests) to maintain product consistency

● High Production Capacity & Reliable Delivery

✅ In-house manufacturing & automated production to enhance efficiency

✅ Fast prototyping & mass production capability, ideal for bulk orders and urgent requests

✅ Worldwide shipping to North America, Europe, Japan, and Southeast Asia

● Cost-Effective Solutions to Reduce Business Expenses

✅ Flexible MOQ (Minimum Order Quantity), making ordering easier for small and medium-sized businesses

✅ Optimized cost-effective solutions to reduce production and maintenance costs

✅ Custom packaging & laser engraving (logo or model number printing) to enhance brand identity

● Professional Technical Support & After-Sales Service

✅ Expert technical team to assist in material selection and sealing solution design

✅ Rapid response to customer needs, providing prompt technical consultation and solutions

✅ Long-term partnership, continuously optimizing products to strengthen your market competitiveness

- Download

How do L&J's AS568 O Rings improve automotive fluid system reliability?

Our precision-manufactured AS568 standard O Rings provide consistent compression set resistance and excellent sealing integrity for automotive fluid systems. With standardized dimensions across international specifications, L&J's sealing solutions ensure perfect fitment in hydraulic braking systems, fuel delivery components, and transmission assemblies, minimizing leakage risks and extending service intervals. Request our comprehensive specification sheet to match the exact O Ring dimensions for your automotive application.

With 17 years of specialized experience in rubber manufacturing, L&J has established itself as a trusted vertical integration supplier for critical sealing applications. Our standard O Rings and X Rings are available in various materials including NBR, EPDM, Silicone, Viton, and custom compounds to accommodate different pressure ratings, temperature ranges, and chemical compatibility requirements. Detailed specifications are available for download, and our engineering team stands ready to assist with technical guidance for your specific sealing challenges.