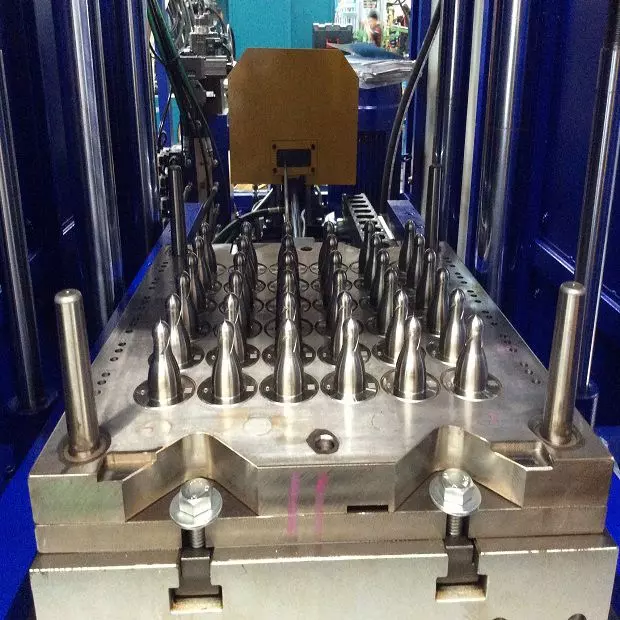

High-Precision Custom Rubber Injection Molds

Custom Rubber Injection Molds Manufacturer

L&J International has been specializing in high-precision rubber injection molds since 2006. Our advanced flash-free injection molding process ensures minimal material waste while maintaining superior product quality.

To do mold test, we usually require the compound rubber from customer in order to 100% simulate the working conditions at customer's side. The more details we notice with good communication, the higher possibility that we can successfully make a very good quality mold. Besides, doing mold test, we not only provide samples for your evaluation, we will also provide the related production parameters of mass production as your reference which should be able to save your time of study to the best working conditions of operating your molds.

For more information in detail, please make contact with us.

Key Advantages:

- Custom Design Solutions – We provide tailored mold designs to meet specific customer requirements, ensuring seamless integration into their production processes.

- High-Precision Manufacturing – Utilizing state-of-the-art CNC machining, our molds offer exceptional durability and accuracy.

- Strict Quality Control – Each mold undergoes rigorous testing before delivery, ensuring reliable performance and optimized production parameters.

Application

Our injection molds are widely used in automotive, medical, electronics, and other industries requiring complex rubber component manufacturing.

- Download

Tags

Why Is Proper Mold Testing Critical for Automotive Rubber Components?

Automotive rubber components face rigorous performance standards and must maintain consistent quality across thousands of production cycles. L&J's comprehensive mold testing process simulates your exact production environment using your specific rubber compound, identifying potential issues before mass production begins. We provide not just sample parts but complete production parameters that ensure your team can quickly achieve optimal manufacturing conditions. This thorough approach has helped our automotive clients reduce defect rates by up to 35% while accelerating time-to-market for new components.

Our comprehensive mold testing service simulates actual production conditions using customer-supplied compound rubber, guaranteeing seamless integration with your existing manufacturing processes. Beyond providing sample parts for evaluation, L&J delivers detailed production parameters that significantly reduce your setup time and accelerate time-to-market. Our vertical integration capabilities ensure consistent quality from compound rubber through finished products, making us Taiwan's trusted partner for complex rubber molding challenges.